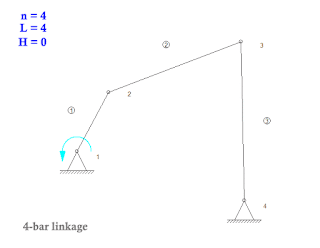

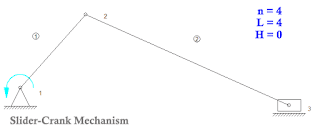

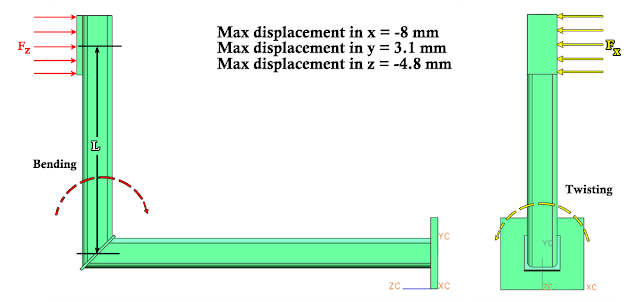

There are a lot of designs of welded parts which are commonly seen. The design A as shown in

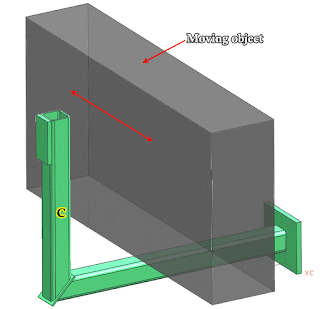

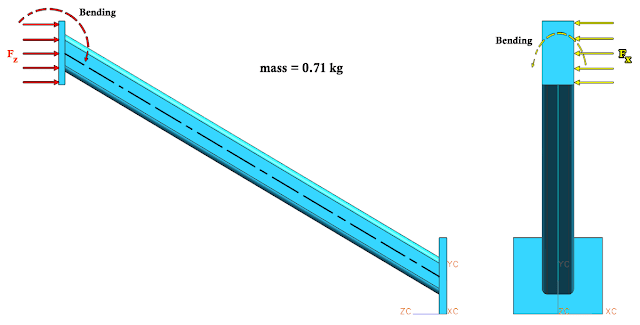

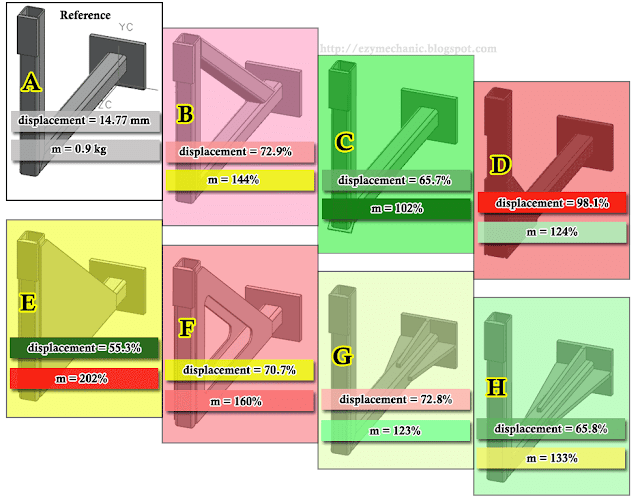

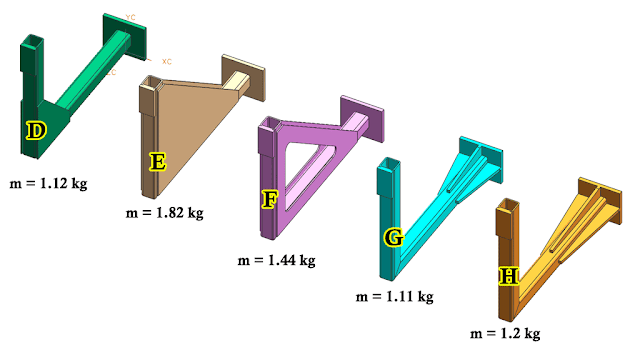

previous post are one of the examples. However, there are some more examples which may seem to be much better than design C. Let's have a look at these 5 more designs and see how stiff they are. Normally, to make the welded parts more rigid, we have to add some more materials. This usually increases the weight (mass) of the part which, in most cases, is undesirable. Therefore, we want to get the design that provides as low as possible displacement with relatively small increases of the weight. These are 5 new designs to consider.

|

| Five more designs of welded parts for stiffness comparison |

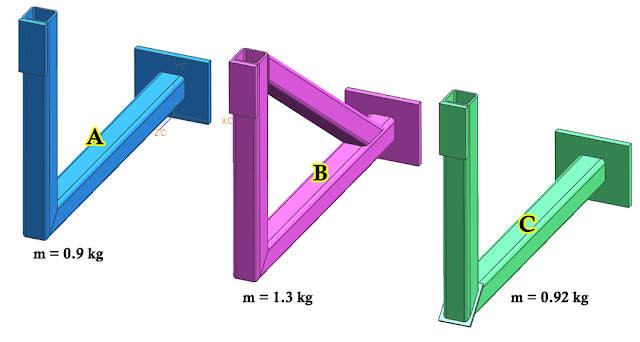

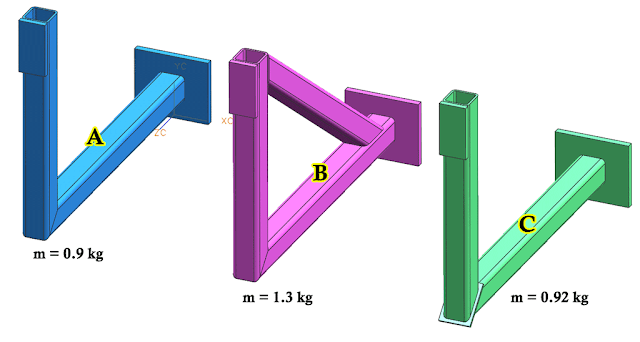

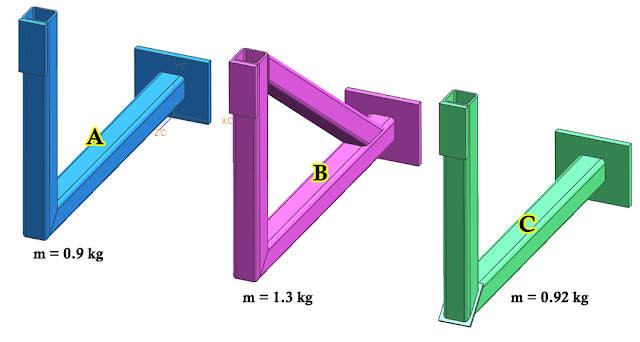

Let's recall the designs from previous post (design A, B and C) in order to compare with these new designs.

|

| Welded parts of previous analysis |

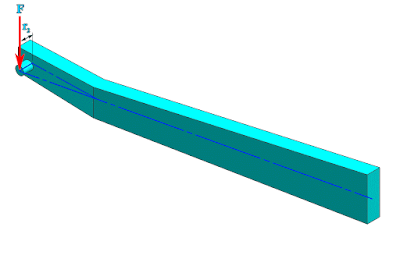

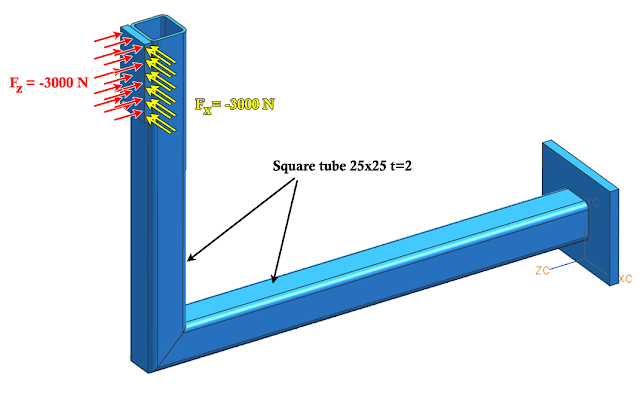

Design C is the best solution compared with design A and B as shown in

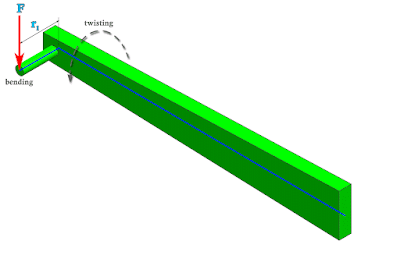

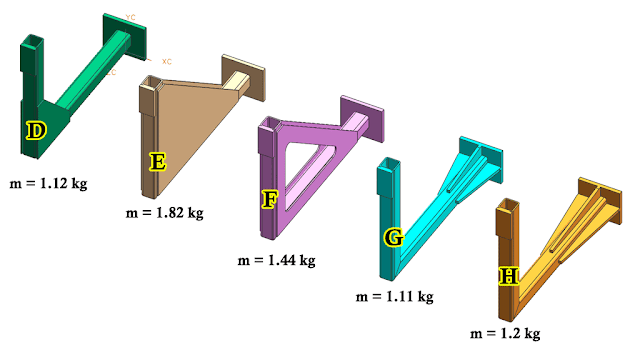

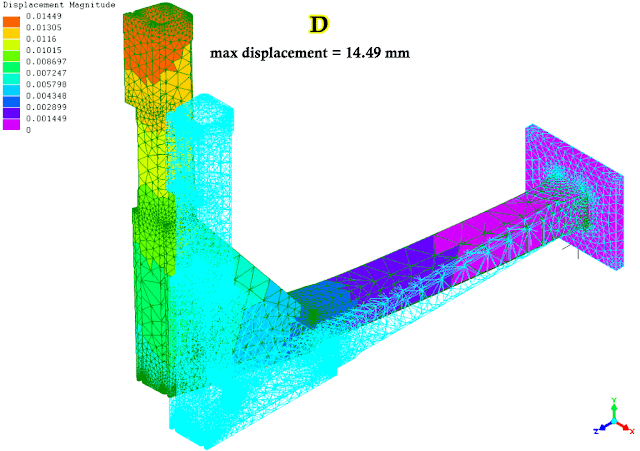

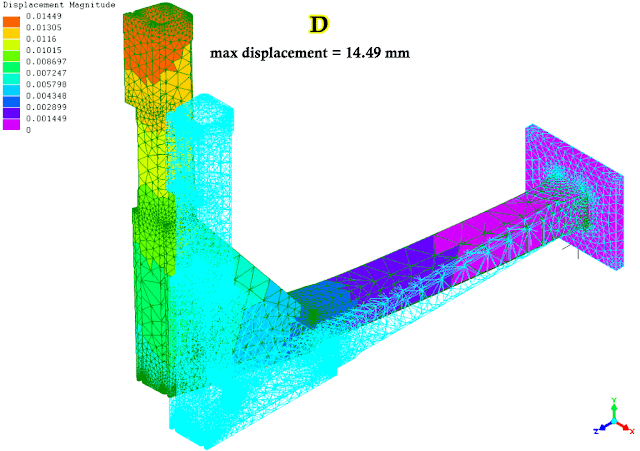

earlier post. However, we may think that design A is not so bad, probably we can add 2 more plates on both sides of the square tubes which will be stronger for torsional load. Because of this, we get design D which we have more masses due to those 2 plates. The mass of design D is 1.12 kg which is 124% of the original mass (design A). What about the displacement?

|

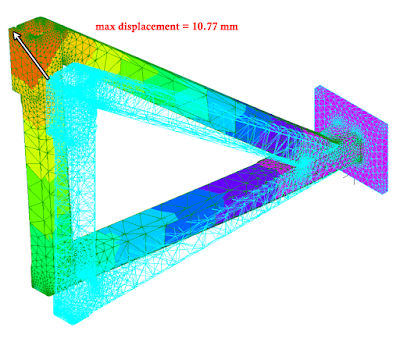

| Finite Element Analysis result: Displacement of Design D |

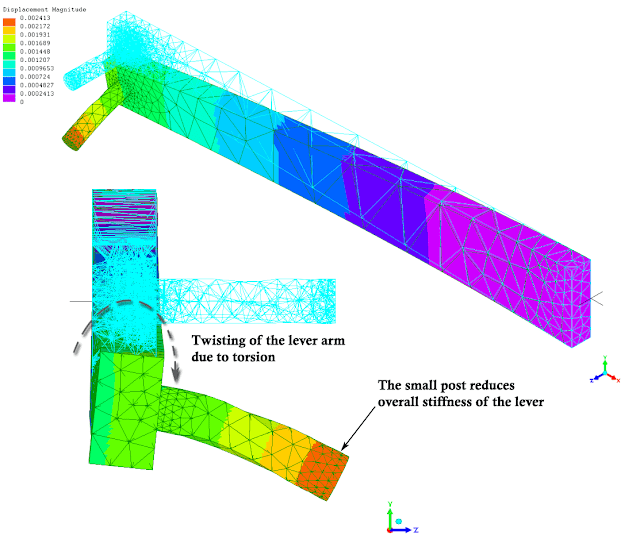

The displacement of this design is in the same level as design A. Design A has displacement of 14.77 mm and this design has displacement of 14.49 mm. The bad thing is that it's heavier by 24% but still has the same displacement. We can see from the

finite element analysis result that there is small displacement on the horizontal tube up to half of its length which is good. But larger displacement starts at the end of the tube. Length of the rib is not long enough to prevent the horizontal tube from twisting.

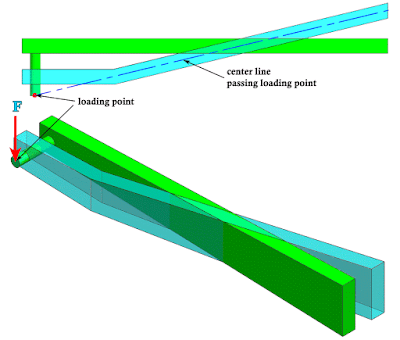

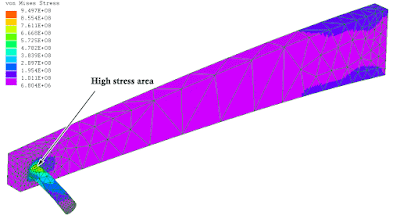

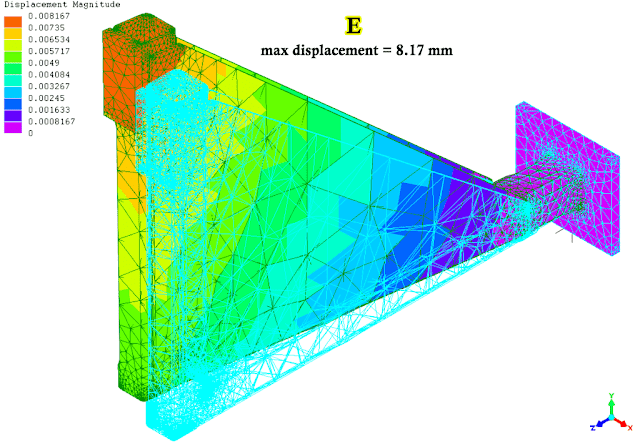

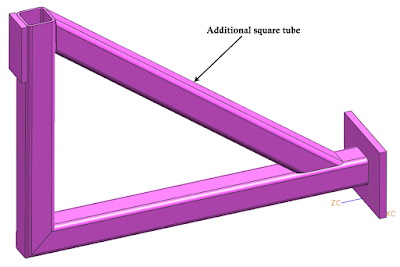

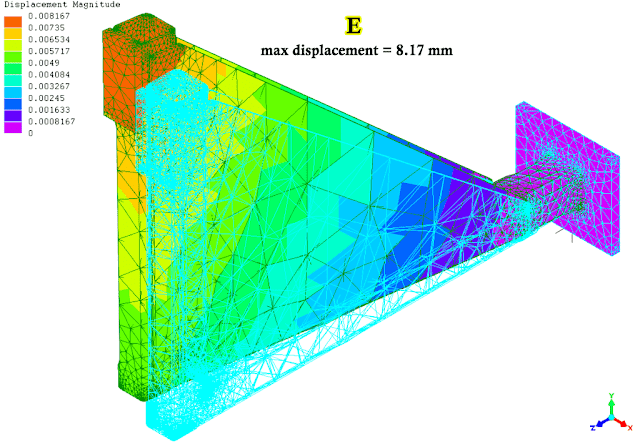

Then, we have a new improvement by making those 2 side ribs larger as shown in design E. We expect to see much reduction of displacement because the ribs are all over the length of the tube.

Here is the FEA result.

|

| Finite Element Analysis result: Displacement of Design E |

The displacement is much less as expected. It has only 8.17 mm which is only 55.3% of the original design. We can reduce the displacement almost by half since those ribs make it strong against torsional load. However, we have to sacrifice much more weight. Total mass becomes 202% of the original design. So it's rigid, but heavy. Probably, we can reduce some weights but still get good stiffness.

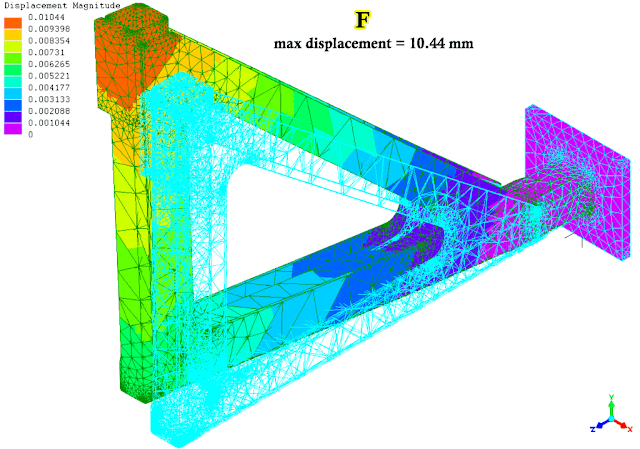

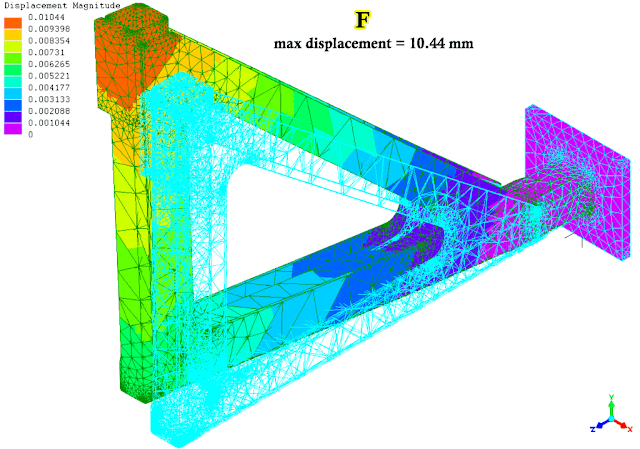

We then have Design F which both side ribs are cut to reduce weight from 1.82 kg to 1.44 kg (160% of original mass). It's still quite heavy, but let's see the displacement.

|

| Finite Element Analysis result: Displacement of Design F |

This design is still not good since it's heavier than design C and has more displacement than design C. So among these 3 new designs, design E is the most rigid design but it's too heavy.

Let's continue in the

next post for the remaining 2 designs.